Rigid Boxes

Get a Custom Quote

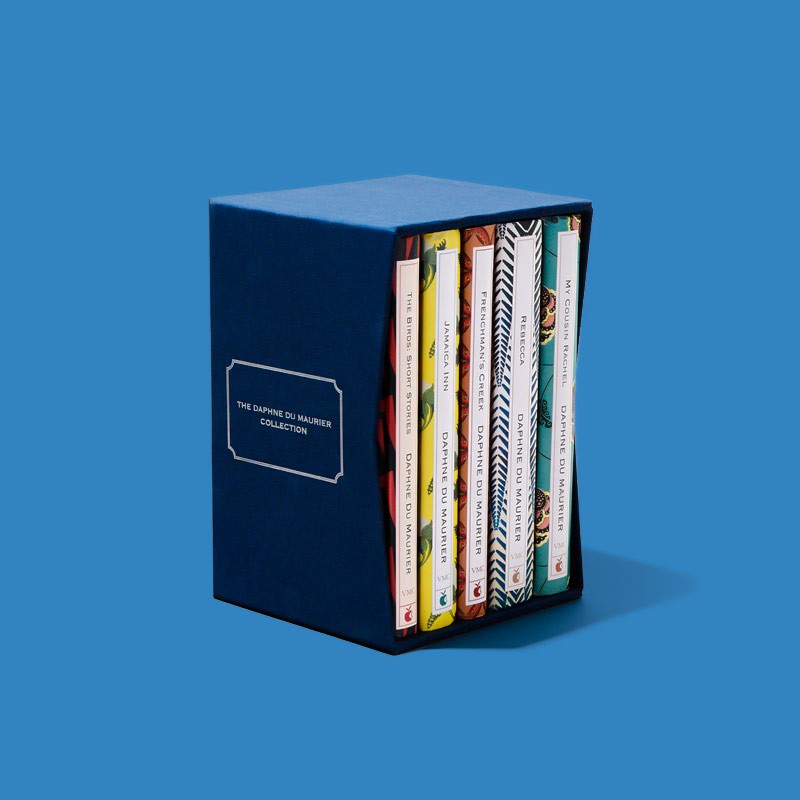

Custom Rigid boxes are also called setup boxes, making them a popular choice for luxury packaging and sleek designs for stunning displays. However, these boxes feature premium, high-end, expensive, and luxurious product displays. With their higher durability, these boxes are highly recommended for fragile, delicate, and luxury products to retain safety and present them respectively. Since rigid stock and paperboard are the innovative options to meet the protection level.

Additionally, to give the rigid packaging wholesale a more sleek and vivid look, you can use special finishings, like foiling, laminations, embossing, and AQ coatings. And these boxes are best used for gifts, jewelry, and cosmetic items. Let’s look deeply at the rigid packaging boxes, why they are essential, and the key features that make them important.

What are Rigid Boxes? Are Rigid & Setup Boxes the Same?

Personalized rigid packaging boxes are highly durable as they are made of thicker paperboard or chipboard paper to enhance the protection level of the boxes for fragile items. However, rigid & setup boxes are the same.

Rigid containers are worth it due to their luxury, modernity, and sleek look & feel to present items innovatively. And these boxes are the perfect solution for the products like board games, gifts, and highly luxurious jewelry items.

What are the Particular Types of Rigid Boxes?

Customization lets you create the boxes to meet your product’s packaging needs perfectly, and you can shape the boxes to stand out as distinct, premium, and luxurious. However, these boxes are highly strong, superior, and more branded than the corrugated, folding cartons and other special packaging containers.

Additionally, custom rigid packaging boxes majorly come in two types such as:

Partial Finish

The partial finish is the common type used to finish the inner edge of the boxes. However, the special chipboard material inside must be unfinished and visible to keep the rigid boxes wholesale free from toxicity, as the chipboard used internally is a piece that is perforated, creases lines, and folds.

Additionally, the perforated crease lines are optional, letting you secure the paper material before wrapping. And you can use the coating on one side of the boxes with kraft or white.

Full Finish

Unlike partial finishing, the full finish wraps entirely inside and out, and none of the sides of the chipboard remain open. However, the chipboard from the inner side is a separate piece for each face of the boxes.

Furthermore, there is no need to tape the box before wrapping it as the chipboard comes with a high thickness of 2-3 mm. And you can laminate the paper with different finishing options.

Various Innovative Styles for Rigid Packaging Boxes

With the evaluations and innovations in packaging trends, unique and modern packaging is increasingly in demand among customers. But the question is how to create packaging that appeals to the modern and branded touch. Hence the custom boxes manufacturers assist you with the endless styles to choose from.

However, this is what you can do through the customizations. The box style plays a keen role in shaping the boxes to the next level. However, we provide you with endless styles to choose from that perfectly fit your needs.

Here are some of the innovative styles:

-

- Tube packaging

- Magnetic closure boxes

- Drawer Style Boxes

- Book Style Boxes

- Shoulder Neck Boxes

- Rigid Candle Boxes

How to Create a Rigid Box from Scratch?

As early mentioned earlier, these boxes come with a highly secure, premium outlook and are vibrant to enhance the branded image of the product. But how to create boxes that reach superior quality and speak volumes?

There is a need for knowledge and professional skills for customization and printing. But before diving into cutting the paper to meet the functionality, you must explore the latest trends of custom rigid boxes and customers’ preferences for the perfect solution.

Here are some essential steps we at Ideal Custom Boxes follow to meet the perfections. Let’s explore in depth how to create such boxes from scratch.

Perfect Measurements – As the paper material is flat, you can cut it according to your product measurements. However, you must first measure your product from different aspects like length, depth, and height for premium solutions.

Folding – However, when you cut the paper to meet the measurements of your products, the next is to fold the paper to secure the base of the box and glue the parts to shape the box.

Printing – Printing is necessary to innovate the visual outlook of the box. However, you must print different elements like logos, taglines, and other details. However, you must apply special finishing options like lamination, add-ons, and coatings to create the desired designs.

Wrapping – When the box is finalized, it is ready to place the items tightly inside it. However, these boxes with secure wrapping make the packaging, shipping, presentation, and shelf-life ideal.

Why Should You Use Inserts?

As rigid telescopic boxes are highly secure and innovative for packaging sensitive products, you must use inserts in the boxes to enhance the security level for luxury items. And why should we use it? Fragile items like jewelry are highly sensitive, and a little scratch can ruin productivity and quality, and no one will be ready to buy the useless product.

However, the foam inserts keep the items safe inside and don’t allow the products to shake with the box’s wall. However, there are several types of inserts that you can choose according to the product’s preferences, such as:

- Foam inserts

- Paperboard inserts

- Corrugated inserts

- Rigid chipboard inserts

- Pulp packaging inserts

Foam inserts are the most popular choice for custom luxury boxes to keep the items safe and secure. However, for sensitive products, you can use foam inside the box, while for the other scratch-resistant items, you can use cardboard or paperboard, whatever you feel better.

What are the Advantages of Customized Rigid Boxes?

Custom rigid boxes come with endless benefits and help boost brand identity and take sales to the next level. However, the superior quality of the box ensures the high-end products’ safety for transportation, presentation, and enhancing shelf life.

And when it comes to reaching a higher potential of customers, it is a must to add a branded touch. Such premium boxes with innovative looks are the perfect tools to win customers among many products.

Let’s discuss some of the essential advantages that give a quick boost to building the branded image of the product.

Shiny and Modern Display

The idea behind rigid box packaging was to allow the manufacturers to present their exotic goods in flattering colors. However, real brands make an effort to give their customers a feel of royalty and exclusivity. And with sleek and modern styles and designs, these boxes are innovative solutions to present the products innovatively.

A Brand Marketing Tool

Personalized magnetic closure boxes with simple and unique designs can transform an ordinary product into a high-end and luxury type. However, the more innovative the products display will be, the more they will be branded and luxurious. However, a custom printed rigid box with a logo can help elevate your brand to a new height.

Amazing Way to Display Products

Customized display of the boxes helps capture the customers as it creates a first impression at first sight by looking at the boxes. Amazing looks always win the customers to grab the products. And when you’re with the custom rigid boxes, it grabs attention and helps build the branded image to enhance sales.

Attractive and Eye-Catching Design Ideas

You may have endless options for customizing the boxes’ design to appeal to the products. However, the appearance of the products affects the products in a big way. The buyers and other people who witness the products can think about purchasing them shortly.

Therefore, it gives great marketing leverage to the brands. A good design helps the brand to make a good impression on the customers and builds up the brand’s integrity.

Deliver a Broad Range of Personalization Choices

The custom boxes are extremely adaptable and versatile. However, these boxes are not bound to the product dimensions at all. And no matter what type of products you are willing to sell, you must first accommodate your requirements.

In addition, Ideal Custom Boxes, as a luxury rigid box manufacturer, the designing experts have years of experience in the subject, and we take care of all the important factors. Therefore, these products are one of the top-selling brands of this corporation.

Highly Protective and Durable

There must be more than a thin layer of cardboard or paper to contain more than 250 gm of products. As the product’s weight increases, it becomes impossible for a thinner container to hold it securely.

Under these scenarios, branded rigid boxes act as the answer to this problem. However, these products’ strong design and structure are perfect for heavier products. And these boxes are also ideal for safekeeping the products during transit.

| Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | Standard Turnaround Time: After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time: Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

| Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL, Port to Port |

frequently asked questions

Yes, we can expedite your order and get the boxes to you in 6-8 business days with a small fee.

Yes, We have thousands of running customers in Canada, Australia, UK and USA. Our services are available all around the world without any shipping charges.

We will provide you with a 3D digital illustration of the boxes so that you have a better idea of how your boxes will look once they are produced. Also, we offer free physical sample of your own boxes on bulk orders so that you can check if everything is as per your requirements.

You can place an order with us with these 4 easy steps:

1- Fill out the “Get A Quote” Form.

2- Upload your artwork or email it to us.

3- Provide approval on the digital proof.

4- Once the payment is made we will send your boxes to production.

You can easily track your order by call us at (+1 940 257 2957) or you can contact the sales representative who is assisting you on your project.

-

What are rigid boxes?

Rigid packaging solutions are the perfect solutions as they are durable, creative, innovative, and stunning to ensure the products' safety and present as innovative. However, these boxes are also known as rigid setup boxes or gift boxes and are commonly used for luxury and premium products due to their elegant and upscale appearance. -

What makes a custom rigid box with a lid different from other types of packaging?

Rigid containers come with many features that make such boxes perfect options for packaging products. However, these boxes are characterized by their unyielding structure, which provides superior protection to the product than the standard folding cartons or corrugated boxes. -

What are the advantages of wholesale rigid boxes?

These boxes offer endless benefits for the presentation and provide excellent protection for delicate items. However, you can shape these boxes with various finishing options, such as embossing, foil stamping, spot UV coatings, and debossing. -

Are custom collapsible rigid boxes eco-friendly?

Yes. but it depends on the particular product's needs. However, these boxes can be made from sustainable and recyclable materials depending on your needs which makes these boxes more environmentally friendly. -

How rigid box factory assemble the boxes?

Rigid packaging boxes are pre-fabricated and typically shipped flat to the end user. However, they create the boxes with pre-scored lines and magnetic closure, making them easier to open and close. -

What closure options do rigid paper box suppliers provide?

When it comes to choosing the closure for a custom box, you may have various options, such as magnetic closures, ribbon ties, snap locks, and clasps. However, the closure enhances the overall functionality and user experience. -

How do luxury rigid box manufacturers USA provide branded packaging?

When it comes to getting custom boxes from professionals, they offer endless options for choosing suitable material, printing, and finishing options. However, you can ask them to add the company logo with premium designs to boost product perceptions. -

Can you use rigid boxes for seasonal promotions?

Yes. You can use these boxes for the brand's promotion and marketing by printing your company logo on the boxes. However, the rigid boxes are versatile and can be tailored to suit seasonal promotions or special occasions. -

Can you customize the magnetic rigid boxes?

Yes. these boxes are highly customizable as they are created from paperboard and chipboard. However, you can choose from a wide range of sizes, shapes, colors, materials, and finishing techniques to create a unique packaging solution that aligns with your brand image. -

What industries commonly use rigid box packaging?

Rigid wholesale boxes are versatile and widely used in particular industries where product presentation and perceived value are essential. Such industries are:

- Cosmetics

- Electronics

- Fashion

- Gourmet foods

- High-end consumer goods

Yes. These boxes are highly customizable as they are created from paperboard and chipboard. However, you can choose from a wide range of sizes, shapes, colors, materials, and finishing techniques to create a unique packaging solution that aligns with your brand image.