Tuck End Boxes

Get a Custom Quote

No matter what type of business you do, custom boxes with remarkable printing are necessary. It is the basic demand of customers and the modern market. These boxes ensure product quality and reflect the branded image that is enough to influence sales. Moreover, with printed logos, such custom tuck end boxes can speak with the customers, tell them your brand story, and make a difference from other brands.

It is a crucial thing to set a brand apart from the competition. However, among several brands, winning a customer is possible with unique style, appealing design, and stunning outlook that displays the products’ worth. Let’s look deeper at what custom tuck end packaging boxes wholesale are.

An Overview of Tuck End Boxes Style

Want to know about Custom Tuck End Boxes? These are special boxes made from paper material, having two sides that can be tucked. Usually, the two tucked sides are closed in the same or the opposite direction. However, these secure tucks ensure that the products remain safe and intact.

In addition, these flaps are secure enough to keep the products enticed. Such boxes have flaps at both ends that are closed in the same or opposite direction. However, this tucking of the tube varies from product to product.

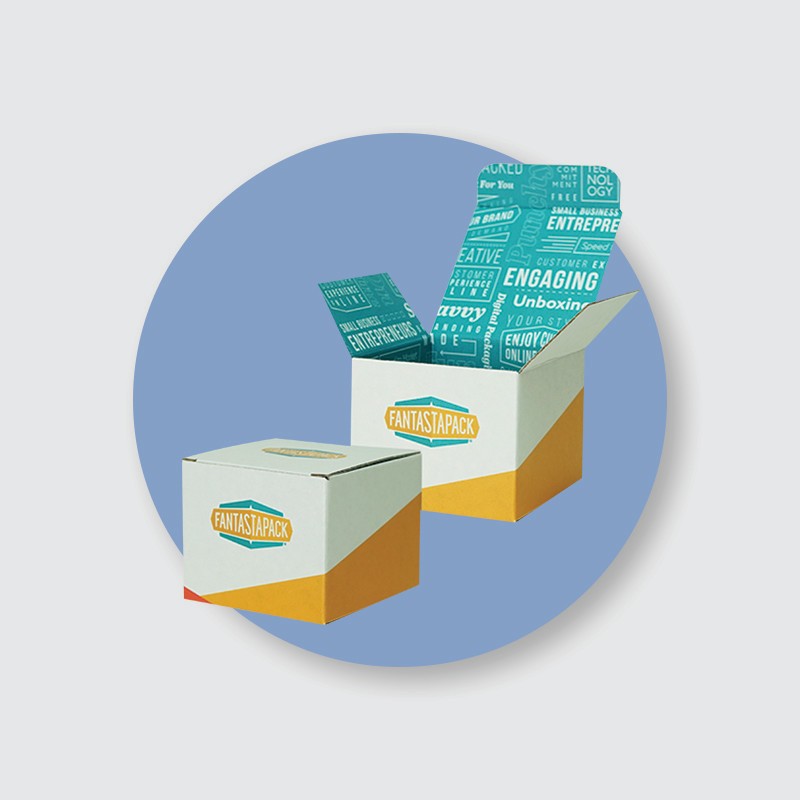

Moreover, these boxes are for wrapping multiple types of products because of their convenience and the impressive outlook that they provide. You can wrap and store your products in Kraft boxes wholesale for a great unboxing experience.

What are Different Types of Tuck End Packaging Boxes?

There also are two types of tuck boxes: straight and reverse tuck ends. However, RTE is a type of tuck-end box that is rectangular and uses a side closure method. These are also made up of cardboard or kraft paper material, while the quality of paper and printing depends on the product’s needs. The reverse tuck-end boxes are typically used in the packaging of cosmetic products.

Straight Tuck End Boxes (STE) are another type of tuck-end box. They are costlier than RTEs. This type of product carrier is more common than any other type of these boxes. Mostly, STE is used in pharmaceutical packaging, candies packaging, cosmetic packaging, and many more. Due to their creative shapes, they are used for versatile purposes.

What are the Benefits of Using Custom Boxes with Tuck Ends?

Wrapping products in style is worth it for building a first impression. But choosing an appropriate style for product packaging also matters. When you produce cosmetics products, retail or wholesale, a custom printed tuck end box can be a perfect solution. However, it is unique, appealing, innovative, and reliable for wrapping products.

Further, these boxes fulfill customers and market on-demand packaging and marketing needs. Well, a unique box can reveal branded features of the products and let the customers explore more about the brand and influence sales. There are various features that such boxes come up with. Let’s explore them in detail.

Budget-Friendly Packaging Solution

These boxes are made from cardboard, kraft, or paperboard materials that are cheap. Custom tuck end box manufacturers use such paper types with specific quality depending on your product’s needs.

However, choosing the finest paper quality leads to highly durable solutions that keep products safe. Still, adding unique graphics and textures on custom tuck end boxes may not exceed your budget but can enhance visual perceptions and add value to the product.

Custom Sizes and Shapes for Particular Products

Although not every product is the same in every aspect, it is important to have packaging that showcases them as unique and complete. However, the size, shape, and design of the box must be unique and appealing. With the unique shapes and sizes of these boxes, they are ideal for wrapping products and preventing damage.

Moreover, there are no limitations to customizing them with on-demand needs. So, you can measure all your products accurately to craft custom cosmetic boxes that ensure snug and safe storage. Moreover, since they are also intact, product safety is also ensured in this type of box.

These boxes are a perfect fit for lightweight products. For example, if you run a sweets shop, then these boxes would be the best choice for you to consider as your daily driver in the packaging. They have enough space to accommodate such products.

Better Customers Communications

Strong bonding with potential customers is necessary to keep them enticed with your brands. However, it is possible when you fulfill their requirements. On-demand tuck end boxes with logos are necessary to make customers feel special and build an emotional connection.

Custom packaging is all about gaining customers’ attention and letting them know about the new and special features of your product that set it apart. However, if you work hard in building the quality but don’t care about the presentation, you will spoil your brand image. And this will lead you to ground off your business.

Versatile for Packaging Various Types of Products

Don’t worry about the packaging boxes. If you run a business producing multiple products with particular natures, fragility, cost, and importance, custom tuck end boxes with respective sizes, shapes, and styles are necessary.

But you can choose the paper type and quality depending on the protection level and aesthetics. These boxes are good enough to use for wrapping cosmetics, stationary, retail, and pharmaceutical products. However, the type of tuck end depends on the product.

You can choose a straight tuck end vs reverse tuck end, whatever best suits your needs. They are designed in a way that allows a company to showcase its products effectively and efficiently.

On-Demand Printing Opportunities

Nowadays, printed cosmetic boxes are valued by customers when buying a product. However, such boxes let them know the important features of the products and give reasons why they should choose such items. So, the printed product and brand details on these boxes are merely important for selling your products.

These boxes are perfect for explaining the product’s value in the consumer’s mind. Their easy customization enables an organization to put their favorite colors, their brand name, and brand logo on the top of the box. But how? Custom box suppliers in USA help you professionally print and align the elements in the right place that add value.

| Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | Standard Turnaround Time: After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time: Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

| Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL, Port to Port |

frequently asked questions

Yes, we can expedite your order and get the boxes to you in 6-8 business days with a small fee.

Yes, We have thousands of running customers in Canada, Australia, UK and USA. Our services are available all around the world without any shipping charges.

We will provide you with a 3D digital illustration of the boxes so that you have a better idea of how your boxes will look once they are produced. Also, we offer free physical sample of your own boxes on bulk orders so that you can check if everything is as per your requirements.

You can place an order with us with these 4 easy steps:

1- Fill out the “Get A Quote” Form.

2- Upload your artwork or email it to us.

3- Provide approval on the digital proof.

4- Once the payment is made we will send your boxes to production.

You can easily track your order by call us at (+1 940 257 2957) or you can contact the sales representative who is assisting you on your project.