Child Resistant Packaging

Get a Custom Quote

Customers prefer to buy a product that has attractive & sturdy packaging. Why is this so? It is because of products’ importance and fragility to break up quickly. Meanwhile, Custom Child resistant boxes are a great way to package the product for more prolonged use.

Moreover, adults seem to care less about product safety. So, this is why customized boxes are essential for them to carry luxury products. Then if the packages are fragile too, they can’t ensure product safety.

And the customers will fully distrust you for the next purchase. However, custom packaging directly impacts making the product safe, building customers’ trust, and convincing them to buy.

Why Is a Child Resistant Packaging Solution Essential?

Are you searching for why child resistant pouches are necessary for pharmaceutical businesses? Let’s learn in depth. Most pharmaceutical products are made of a mixture of cannabis with other components. Meanwhile, it is excellent for treatments.

Custom packaging is necessary for the pharmaceutical business to package products efficiently & safely. Meanwhile, it is a great way to educate youngsters about marijuana and its legal uses in medical industries.

Different Types of Material Used for Making Child Resistant Box Solutions

Material selection is critical because it is the first step to premium packaging that speaks up to the customers. However, the durability & efficient surface for high-quality printing depends on the quality of the material you choose. Therefore, be wise while deciding on suitable material.

Let’s explore some unique materials below:

- Kraft Paper

- Paperboard

- Cardboard

- Rigid stock

- Bux board

- Corrugated stock

You may find all the above material options. So, it is up to you what type of packaging you need. At the same time, cardboard is a widely used material in overall custom product packaging because it is less expensive.

Moreover, if you want enough security, Kraft and rigid stock are excellent options for extraordinary box solutions. Meanwhile, you can also use corrugated material for making heavy cartons to carry the products in a single carton.

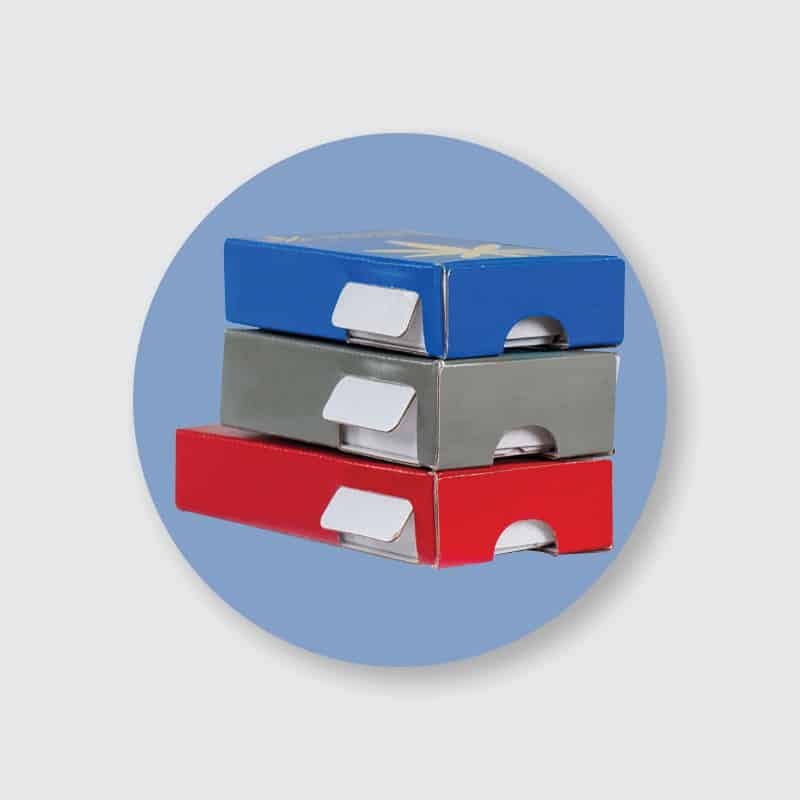

Various Styles of Child Resistant Packaging Solutions

Many packaging industry laws exist to safeguard consumer safety, and no group is more vulnerable and in need of protection than children. Adult-only goods, from cleaning agents to pharmaceuticals and insecticides, can be dangerous or even fatal if consumed by a youngster.

As a result, the state and federal governments and other regulatory authorities have devised regulatory rules to prevent children from obtaining unsafe items. Some creative and unique styles are:

- Tuck-end boxes

- Tuck-top boxes

- Window boxes

- Tuck Flap Box

- Pillow Box

- Gable box

- Sleeves Packaging

Above are some unique and mostly used box styles used in pharmaceutical businesses. So, if you are running such a business, you can choose an appropriate one that should be further customized in a creative and informational way.

What are the Different Features of the Child Resistant Boxes?

The use of child-proof concentration jars assures children’s safety. Due to safety issues, many goods are not suitable for children. Bleach, pharmaceuticals, and home items are all examples. When carried home, custom child resistant locks for rigid boxes decrease the danger of ingestion.

Furthermore, youngsters unknowingly consume dangerous edible cannabis products such as gummies or brownies. Because edible cannabis contains a greater dosage of THC, it is packaged in child resistant packaging wholesale, making it difficult for children to open.

Child-resistant concentration jars are helpful for drugs and vitamins that youngsters should not take. Kid-proof seals around bottle tops keep pharmaceuticals safe and prevent a child from eating them. However, durable packaging, including complete details, is essential.

Great Opening Experience of Boxes

Child-resistant pill lids are opened by simultaneously applying downward pressure and turning the cap counter-clockwise. Although this is perhaps the sort of child resistant opening mechanism that is most commonly known, there are other options.

Most pharmaceutical Child proof packaging regulations require the folding carton to have a resistant design and bar kid access for a product to comply. According to the law, child resistant folding boxes must be very challenging for youngsters under five to open while being manageable for adults.

High Durability for Product Safety

Product safety is the most crucial consideration that may be hazardous to customers and children. Customers will only buy a package if it looks to be safe. This can be harmful to a company’s image.

Following the completion of a hazard analysis, businesses should consider a choice of available kid-resistant packaging options. There may be more than one solution that will work for the product but choose the suitable one. This is crucial for three reasons:

- Children adapt to typical child resistant packaging wholesale, rendering previous options worthless. Outdated packaging that appears outdated does not reflect well on a current brand.

- Consumer preferences shift. Packaging typical of a decade ago is no longer as appealing to consumers.

- Newer packaging options are being created that are both safer and provide a better customer experience.

Instructions for Sensitive Products

Warning labels exist on child resistant paper boxes wholesale to make sure that customers are aware of the dangers and may take action to protect themselves and any children from damage. Custom CBD Boxes cover anything from choking hazards to potentially harmful pharmaceuticals.

There are tight, precise, and frequently changing labeling regulations in an emerging sector like cannabis goods. Labels must include details like THC levels, doses, and strain type, to mention a few, depending on the cannabis product and the state.

Why Ideal Custom Boxes are Best for Premium Box Solutions?

Working with a reputable supplier that provides child resistant concentrate packaging is critical to make your goods safe for children. “Ideal Custom Boxes” assists you with pleasing and informative packaging to make it customer-oriented sales.

Please get in touch with us if you have any questions regarding our goods or services. Also, how we can assist you. What makes us best? Let’s take a look!

- Supportive Team

- Many years of experience results in premium

- Quick turnaround time

- Free-of-cost shipping

- Free Design Assistance

- Exception box solution

- Delivery on time

Conclusion:

Pharmaceutical products are more widely used than ever. Meanwhile, you need to invest in customized Child resistant cannabis boxes to meet market trends. While, Ideal Custom Boxes is a one-stop packaging solution assisting you with exceptional packaging solutions in an appropriate manner, with both quality and design.

These boxes are great for branding since they are created specifically for you and will help you stand out in the crowd and boost sales. Customizing CBD sticker labels is a successful marketing technique. Nowadays, cardboard boxes are rarely used to package CBD lotions, preferring sticker labels instead.

| Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | Standard Turnaround Time: After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time: Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

| Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL, Port to Port |

frequently asked questions

Yes, we can expedite your order and get the boxes to you in 6-8 business days with a small fee.

Yes, We have thousands of running customers in Canada, Australia, UK and USA. Our services are available all around the world without any shipping charges.

We will provide you with a 3D digital illustration of the boxes so that you have a better idea of how your boxes will look once they are produced. Also, we offer free physical sample of your own boxes on bulk orders so that you can check if everything is as per your requirements.

You can place an order with us with these 4 easy steps:

1- Fill out the “Get A Quote” Form.

2- Upload your artwork or email it to us.

3- Provide approval on the digital proof.

4- Once the payment is made we will send your boxes to production.

You can easily track your order by call us at (+1 940 257 2957) or you can contact the sales representative who is assisting you on your project.

-

Are Child Resistant Packaging for Dispensaries Safe?

A list of medications and household products that need to be put in child resistant box solutions is also included in the regulation. It's crucial to remember that child resistant packaging is designed to make kids move more slowly. They are not intended to keep them out. -

What qualities should a Child Proof Packaging have?

Custom boxes should be durable for lasting resistance and informative for easy recognition by the audience. However, the box material should be thicker and more efficient for an easy-open tab, corner, or flap. -

Why are Custom Child Resistant Locks for rigid boxes?

Child resistant packaging means the resistance should be opened, tampered with, or damaged by the child. However, these boxes are created in such a way as to keep the medicine safe from the child. -

Which medications need to be stored in child-proof Product Holders?

All medicines are made of some mixture of chemicals, so all legend medications and regulated hazardous substances must be packed in child resistant boxes. -

Why should you use Child Resistant Packaging For CBD Products?

Child-resistant packaging is intended to lessen the possibility of kids successfully opening a box and consuming potentially dangerous items. Many things, including medicines, cleaning supplies, tobacco products, and edible or inedible plants, are not meant for young children. -

How do you unzip Child Resistant Pouches?

You can unzip the pouches by slipping your fingers beneath the flaps until they hit the closing, specifically designed to prevent toddlers from opening them. Meanwhile, the bag will only open with an upward and rolling motion. -

What makes Child Resistant Cannabis Boxes Ideal?

These boxes are designed with features that make it difficult for children to open or access potentially harmful content. These features often include special locking mechanisms, push-and-turn caps, or requiring simultaneous actions that young children may not be capable of performing. -

What types of products commonly use Child resistant paper boxes?

Items like prescription medications, over-the-counter drugs, cleaning supplies, pesticides, and other potentially hazardous substances often come in child-resistant packaging. Additionally, certain cannabis products, nicotine-based products, and household chemicals use such packaging for safety reasons. -

Can adults easily open Child resistant paper boxes?

Yes! While such type of packaging is designed to be challenging for young children to open, adults can typically access the contents with relative ease by following the intended opening procedures. -

Are child-resistant packaging boxes necessary for pharmaceutical products?

Yes! Especially for pharmaceutical products or substances, as they pose a risk to children if accidentally ingested or handled. These packaging boxes serve as a safety measure to prevent accidental exposure or consumption of items.