Bakery Boxes

Get a Custom Quote

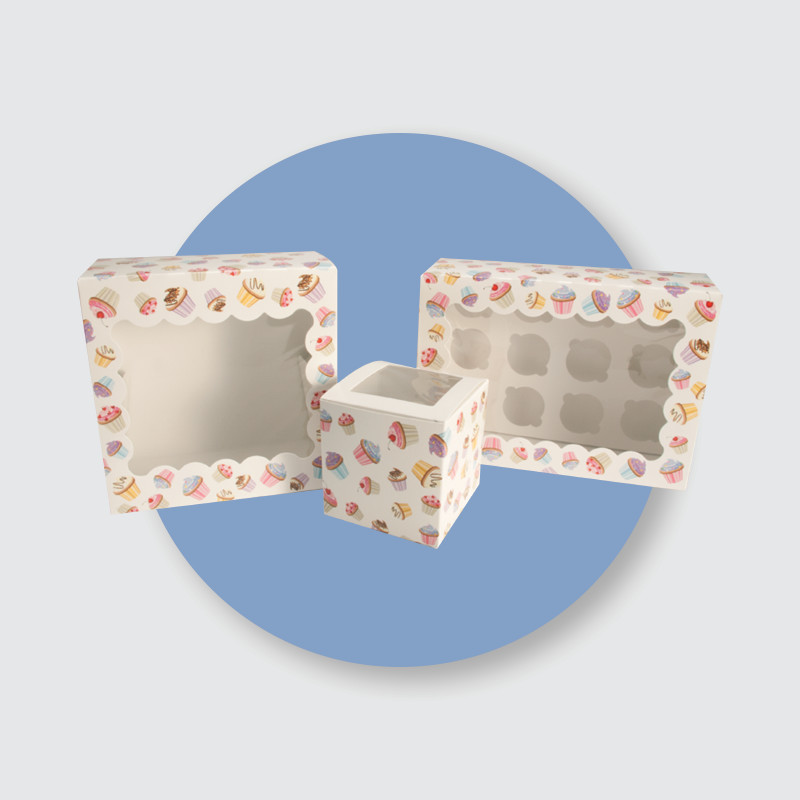

Do you produce delicious cakes and pastries? Are you searching for solutions to prevent your items from being exposed to harmful substances? Custom bakery boxes are ideal to keep the products safe and visually present as creative and tasty. However, these boxes are created to meet specific product’ needs.

As bakery products are fragile and easy to break and lose their original shape, such boxes are great options for packaging and transportation. Customization is easier and you can personalize each box for the specific item with respective sizes, shapes, designs, and styles.

Why is Custom Bakery Packaging Essential?

Running a bakery is not meant to produce a single product. Each customer has different tastes and preferences for cakes and other products. There are various products with specific variations and flavors. So, wrapping each product in a unique box is essential to getting custom packaging. These boxes not only retain product safety but also help to present each item uniquely. Don’t worry about that.

These boxes are relatively inexpensive. You can fulfill your packaging and high-end marketing needs by investing a small amount. In addition, bakery boxes with printed logos are great sources to present your business as unique. These boxes create a memorable impression on the customers to return for purchase.

What Materials Are Used for Creating Bakery Boxes?

Food items are sensitive and need high protection to retain taste and quality. So, wrapping such items in custom boxes requires specific considerations, such as the material being non-toxic. Boxes must not release any toxicity to ruin the food. However, many customers are health-conscious who first ask the salesman about the paper types.

There are many paper types, but cardboard and kraft paper are most commonly used for creating bakery boxes wholesale. These paper types are secure, cheaply available, easy to print, and recyclable. However, you can choose the quality paper if you need high security to retain safety.

Why is Non-Toxic Paper Type a Must?

Paper type matters, especially when it comes to wrapping the food items. Custom Food boxes must be secure from inside and out. However, secure boxes can prevent damage from external factors. But what about the inside of the box? Cakes, doughnuts, pastries, and sweets are soft and oily.

Therefore, before getting the paper material for such items, you must ensure that the paper does not release any toxicity. Don’t print the bottom of the paper. Sometimes, inks may not be eco-friendly. However, they can release dangerous chemicals which cause food poisoning. So, having eco-friendly and recyclable paper is a must.

Why Should You Get Custom Bakery Boxes for Packaging?

Many bakery business owners ask why they should get custom boxes for food packaging. Are you one of them? There are many reasons why you should invest in getting custom bakery boxes. The major reasons are the products’ safety and presentation.

However, with standard packaging boxes, you can’t ensure that. Frustration-free boxes let you wrap products easily and transport the items safely to the end users. Still, if you didn’t get it, let’s explore some essential reasons.

Secure Packaging & Transportation at End Users

Keeping delicious items safe from internal and external factors is necessary. So, make sure you have selected the suitable paper type. If you find the right solution difficult, get help from custom box manufacturers. They help you get a professional, modern solution to secure your products. So, don’t worry about that.

At Ideal Custom Boxes, we let you choose the paper quality that perfectly fits your needs. However, Kraft and cardboard are durable paper types to ensure safety for packaging and shipping.

Exceptional Visual Presence

Visual presence matters when buying special food items like cakes and sweets. It builds customers’ trust in the quality. Custom bakery boxes build their confidence in productivity, quality, and taste. So, the more secure and attractive your packaging solution, the more customer attention your products will gain. In addition, you can create an attractive and innovative visual presence by printing unique colors, graphics, and pictures.

Customer-Oriented Packaging Solutions

These boxes help you gain more customers and generate sales. But how? With printed details and company logos on the boxes, you make such boxes your branding assistant, communicating with the customers. It helps them choose suitable flavors.

No one will trust the products without any printed details unless they taste them. So, what to print? Whatever you want to display, you can do that. But you must be specific with your descriptions.

Opportunity to Market Your Business

No matter what type of business you run. Branding is necessary whether you have just started or want to maintain its worth among customers. Marketing your business can take that to the next level. But if you don’t do so, your quality and taste will be useless. So, how do you do so, and how do bakery boxes with logos help you achieve marketing goals? It is simple. Your printed logo works as your branding assistant.

Custom Bakery Boxes Reflects Taste and Quality

Sometimes, business owners ask how custom printed boxes with Logo can reflect the branded image of the product. It is simple and nowadays trending to generate sales. Packaging tells the story behind the scene. How will you tell them if you work hard, produce quality taste, and make something different from others?

And you can’t individually do so. It would help to have a marketing assistant who speaks to the customers and tells them about your creativity. However, it is what a printed logo exactly does. It is a specific and unique identity that defines you.

Is Printing and Designing Boxes for Specific Products Easier?

Yes! Technology has made everything simple. However, bakery box manufacturers have the latest technologies for printing and designing. It is simple to personalize boxes for each type of product. But your ideas must be unique and innovative. In addition, for generating suitable colors, you can use color models like CMYK and PMS.

The special finishing effects are great to choose from to make the packaging boxes attractive, unique, and innovative. But make sure you use recyclable ink for printing that doesn’t release any chemicals.

Where to Get Custom Packaging for Bakery Products?

Nowadays, nothing is impossible and difficult. Creating custom bakery boxes for particular products is now simpler and easier. You need a unique idea, and a custom box supplier can make your thoughts into reality. Ideal Custom Boxes are a great option to go through with. However, you can visit the website, look closely at the portfolio to check your professional skills, and then order custom packaging depending on your needs.

| Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | Standard Turnaround Time: After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time: Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

| Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL, Port to Port |

frequently asked questions

Yes, we can expedite your order and get the boxes to you in 6-8 business days with a small fee.

Yes, We have thousands of running customers in Canada, Australia, UK and USA. Our services are available all around the world without any shipping charges.

We will provide you with a 3D digital illustration of the boxes so that you have a better idea of how your boxes will look once they are produced. Also, we offer free physical sample of your own boxes on bulk orders so that you can check if everything is as per your requirements.

You can place an order with us with these 4 easy steps:

1- Fill out the “Get A Quote” Form.

2- Upload your artwork or email it to us.

3- Provide approval on the digital proof.

4- Once the payment is made we will send your boxes to production.

You can easily track your order by call us at (+1 940 257 2957) or you can contact the sales representative who is assisting you on your project.

-

What are bakery boxes?

These are special boxes for wrapping food items featuring eco-friendly, non-toxic, recyclable, and highly secure boxes to prevent food damage from internal and external factors. They are designed to hold and transport baked goods such as cakes, pastries, cupcakes, and cookies. -

What materials are used for creating boxes for bakery products?

Special kraft or cardboard paper with eco-friendly and recyclable features is used to create such boxes since these materials are good enough to ensure product safety and present as safe and quality products. -

Are bakery packaging boxes customizable?

Yes! These boxes are made from paper materials that are highly flexible and customizable for wrapping different baked items. However, you can customize these boxes with various design options, including size, shape, color, and branding. -

How do I choose the right size of box for different bakery products?

The size of boxes for wrapping bakery products depends on the size of the products. Each product type must have a unique box that fits the packaging and shipping requirements. So measure the dimensions of your products and choose a box that provides enough space without being too large. -

Are wholesale bakery boxes eco-friendly?

Yes! These boxes are available in an eco-friendly nature to prevent food items from getting poisoned. However, before getting into customization, you can custom box suppliers to use eco-friendly paper and other materials for printing and design. -

Can I get bakery box packaging in bulk?

Yes! You can get the boxes in bulk depending on your needs since getting boxes in bulk can save a lot of money. Bakery boxes are often sold in bulk quantities, making them cost-effective for businesses. -

Do printed bakery wholesale boxes include windows for displaying the contents?

Yes! It would be great if such boxes included a window to showcase without unboxing the products. However, it makes it easier for the customers to check the quality and flavor and also helps to prevent damage from external factors. -

Are custom cake boxes good for freezing baked goods?

Yes! These boxes are designed to freeze baked goods for longer. However, they are created to withstand freezing temperatures. You can ask a custom box supplier to craft the boxes for freezing baked goods. -

Can bakery packaging boxes be used for shipping baked goods?

Yes! These boxes are designed for wrapping products and shipping to the end users. However, these boxes are strong enough to ensure product safety during transportation and also helpful to reduce damage from internal and external factors. -

Are bakery storage boxes suitable for long-term storage?

Of course! These boxes are not only for secure storage, but they are multi-functional to use. However, printed bakery boxes with printed logos are ideal for brand promotions and marketing.