Custom Toy Boxes

Get a Custom Quote

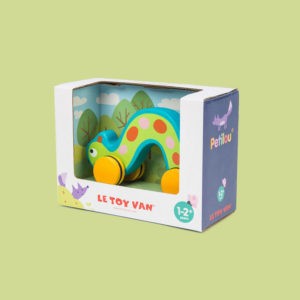

Custom toy boxes are worth it to keep the products safe and show as attractive to grab customers. However, toys are increasingly demanding since these are great sources to please an individual, particularly for kids. However, these toys are often fragile and breakable, so kids don’t care about them. But for a business, keeping them safe, original, and pretty is mandatory unless customers take them out.

Do you own a business for producing toys? It is vital to show off your product as branded to grab attention. But why? Although Kids are the major users, and they don’t care about the quality, they only want a pretty, unique, and creative toy. And walking through the stores, kids pick only those items that have innovative packaging rather than the durability and quality of such items.

What is the Speciality of Custom Toy Packaging Boxes?

Custom boxes are more than you think, and you can make them your branding assistant by investing a small amount. However, these boxes with innovative looks can build a branded image of your products. However, the specialty of these boxes is highly customizable. Although you can play with the paper materials however you want, it needs more forward-thinking to innovate.

In addition, these boxes are durable and can withstand standing taller to retain safety. And hence, custom toy boxes with printed logos can be your assistant in speaking about the brands. And the more innovative storytellers you use, the more it will be able to grab customers and influence sales.

What Makes Custom Packaging Important for Toy Packaging?

Toys manufacturing brands struggle to build their worth among customers, but few achieve their goals. But why have most failed to uplift sales? It is due to their packaging and marketing strategies since the more innovative ideas you use, the more you can achieve the next level.

In addition, mainly for a toy brand, it is a must to wrap the products into visually appealing packaging that retains safety and can help the brand influence sales by building customers’ trust in productivity.

And for a kid, a beautiful, innovative, and eye-catching look matters to buy products. Rather than that, these custom boxes wholesale can play a vital role in standing out from the crowd since a printed logo distinguishes your brand from others and keeps your customers enticed. Here are 5 reasons why are custom toy boxes necessary.

Custom Toy Box Packaging: Ensure Product Safety

Although a creative product is a first choice for a kid, it must be perfect to win their heart. And it is also necessary to maintain your worth as a toy with breakage not only leads to a financial loss but also has bad impacts on the brand’s worth.

And you can ensure product safety by wrapping them into durable custom toy boxes wholesale. But how to make them durable? Customization lets you play with the paper to make it as stable as required. However, for that, it is a must to choose paper material that is good quality.

Modern & Innovative Visual Perception

Nowadays, modern packaging is a must since customers are brand conscious and want something special when buying a toy item. However, the more modern and innovative the product displays, the more likely it will be sold. Rather than that, no one will purchase your products.

And hence, if you are unable to do so, you can get assistance from toy box manufacturers for a more pleasant, innovative, and stylish packaging solution. However, we help you design the box with our modern printing techniques using color models. Color models help in producing several color combinations to meet the best.

Enhance the Brand’s Value

Custom toy boxes enhance the brand’s value. But how? Think about your last purchase; what motivates you to choose a toy? And before unwrapping the products, do you know whether the product is trustworthy? If not, then what inspires you to own that? It may be an attractive visual presentation of the products. However, a creative look among most is a more trustworthy and better option.

In addition, with a printed logo, your toy can be worthwhile. And this is sure about the quality. And build customers’ trust in productivity. Imagine, will you purchase a toy without innovation and a company logo? Absolutely not. And this is why such items are unable to influence customers to increase sales.

Customers Satisfaction

Customer satisfaction is a must. And no one will purchase your products unless they are unsatisfied with your productivity. Although a toy in the box cannot tell the branding story, it can’t satisfy the customers. And if your products are unable to build customers’ trust, you can’t achieve your business goals.

So, how to build customer trust since the packaging is also necessary to secure the products? Don’t worry about it. Cardboard toy boxes are worth it in doing so since an innovative look builds your item’s trustworthiness. However, luxury packaging reflects the brand’s features.

Brand Marketing Made Easier

Branding is a must to spread brand awareness among customers. And the more a brand is popular, the more it will be worthwhile. But branding using commercials leads to loss of wealth, time, and human resources. But when your brand comes to track, the market trends change. And this way, you can never be worthy.

But how to stand out? And what is the perfect way to do so? Custom retail packaging boxes make branding easier with a printed logo. By investing a small amount, you can do branded wrapping and marketing together at a single investment.

What Materials Do You Use to Manufacture Toy Boxes?

Many brands ask what material they require for manufacturing custom toy packaging. There is a bigger list to choose from options that perfectly meet your product’s requirements. But you need to be clever about selecting the perfect materials. However, here are some important materials to utilize to innovate the packaging.

- Paper

- Printing Materials

- Finishing options

The first and foremost thing is choosing the durable paper type for custom product boxes wholesale to retain your product safety. And hence such paper types must include features like durability, flexibility, smooth surface for printing, and easy customization.

Custom Toy Boxes: How to Create Packaging That Speaks Volumes?

Packaging that speaks volumes can increase the worth of your brand. But how to create such types of boxes? It’s easy and tricky to customize. Custom toy boxes must have many features rather than keeping your products safe. However, you must get online assistance from the custom packaging suppliers for a professional toy box. However, here are some creative characteristics each box must include:

- Stable and sustainable packaging

- Packaging with a shiny & innovative visual display

- Boxes must reflect the branded features

- Detail-oriented packaging

- Customers satisfaction is easy

- Set your brand apart

| Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | 100 – 500,000 |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Perforation |

| Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | Standard Turnaround Time: After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time: Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

| Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL, Port to Port |

frequently asked questions

Yes, we can expedite your order and get the boxes to you in 6-8 business days with a small fee.

Yes, We have thousands of running customers in Canada, Australia, UK and USA. Our services are available all around the world without any shipping charges.

We will provide you with a 3D digital illustration of the boxes so that you have a better idea of how your boxes will look once they are produced. Also, we offer free physical sample of your own boxes on bulk orders so that you can check if everything is as per your requirements.

You can place an order with us with these 4 easy steps:

1- Fill out the “Get A Quote” Form.

2- Upload your artwork or email it to us.

3- Provide approval on the digital proof.

4- Once the payment is made we will send your boxes to production.

You can easily track your order by call us at (+1 940 257 2957) or you can contact the sales representative who is assisting you on your project.

-

What is a custom made toy box?

Custom toy boxes are special packaging solutions that are created from scratch with special care. However, these personalized packaging solutions are designed to hold and showcase toys. You can tailor such boxes to match the brand, product, and marketing preferences. -

Why choose custom packaging for toys?

Custom boxes provide lasting security for longer shelf life and safe transportation. However, with a unique branding opportunity, enhance the unboxing experience and offer free and effortless branding and marketing opportunities. -

How do you customize toy boxes?

Customization is easy. But choosing the materials ideally is the matter. You can customize your toy boxes' design, size, shape, color scheme, graphics, and branding elements to create a distinctive look. -

What materials are commonly used for creating kids' toy packaging?

As toys are luxury products, minor damage makes them useless. Therefore, it is necessary to use high-quality paper materials like cardboard, corrugated, or paperboard, which offer durability and flexibility in design. -

Are eco-friendly options available for custom toy storage?

Yes! Paper materials come in different natures, and you can select the eco-friendly depending on your needs. However, there are many packaging suppliers that offer eco-friendly choices for the perfect solutions. However, the recyclable materials and sustainable printing methods make the packaging perfect for environment-friendly nature. -

Why should you print safety information on baby toy packaging boxes?

It is necessary to add special care and usage instructions in the boxes to make for longer survival. it's advisable to include important safety information, assembly instructions, and any required warnings on the toy boxes to ensure proper usage. -

What types of printing options should you choose for creative toy packaging?

Printing the box is necessary to give it a unique, innovative, and appealing look. Various printing techniques, such as offset printing, digital printing, embossing, and spot UV, can be used to create an attractive visual display. -

Can you incorporate a window on the discount wholesale toy boxes?

Yes. You can customize it however you want. Adding a window to the box design lets the customers look at the toy without opening the box. It enhances the customer's experience and product appeal and makes it easier for them to choose the best options. -

Can you use the same toy box design for different toy packaging requirements?

Yes, if you want the same design for your productions. But it could not be better practice. No one can understand new products and their features; however, everything will likely be the same. While a single design can be used for multiple toy products, it's recommended to tailor the box size and shape differently for each toy type. -

Are there any specific guidelines for designing toy boxes with names?

Custom box suppliers provide guidelines to design the boxes with names. However, for optimal results, you must follow such guidelines. Following these guidelines ensures your design looks as intended on the final product.